Die casting is a process that has been used for centuries to create metal parts. This is a process that can be used to create both small and large parts, and a process that can be used to create both simple and complex parts.

In die casting, molten metal is forced into a mold cavity. The mold cavity is created by bringing two hardened steel molds together with great force.

When the molten metal contacts the mold, it cools rapidly and hardens. This will create the part you want.

What is aluminum die casting?

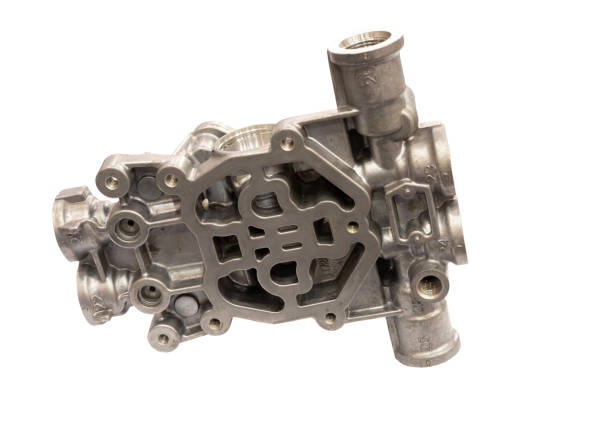

Aluminum die casting is the process of pouring molten aluminum into a mold under high pressure. Once the aluminum has taken shape and cooled, the casting is removed from the mold and excess metal is removed.

Die casting is a very efficient way of making identical parts, so it is usually used for mass production. aluminum die casting service It can be used in a variety of applications, from automotive engine blocks to electronic devices.

One of the advantages of die casting is the ability to produce parts with very intricate designs. Additionally, die casting is extremely strong and durable, making it ideal for use in products that undergo a lot of wear and tear.

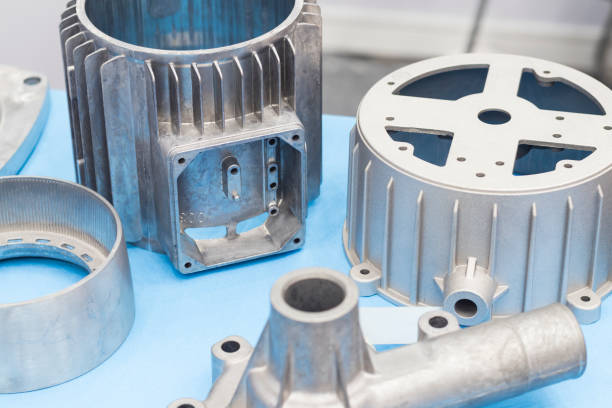

Various types of aluminum alloys available for die casting

Aluminum alloys are classified according to their composition. The most common types of aluminum alloys used in die casting are wrought and cast alloys. Wrought alloys are made by combining aluminum with other metals such as copper, magnesium, silicon, manganese and zinc.

These alloys are strong and durable, making them ideal for use in die casting. Cast alloys, on the other hand, are made by melting aluminum and pouring it into a mold.

This manufacturing process results in a less dense metal that can be more easily formed into the desired shape. casting alloy It is typically used to create small objects such as coins and buttons.

How the casting process works

Casting is the process of creating a mold of the desired shape and filling the mold with material to create an object.

The material used for casting can be anything from metal-like aluminum This process is used for everything from creating sculptures to manufacturing auto parts. To make a mold, you first need to make a mold.

The mold can be made from any number of materials, but it must be able to withstand the heat of the material used to cast it. Once the mold is made, it is placed in a container called a crucible. The material used for casting is heated until it becomes liquid, at which point it is poured into a mold.

Once the material has cooled and hardened, the mold is broken to eject the final product. Casting is a versatile process that can be used to create objects of all shapes and sizes.

Advantages of aluminum die casting

Aluminum die casting is the process of pouring molten aluminum into a mold under high pressure. Using this process, you can create highly detailed and precise parts with a smooth surface finish. Die casting is often used for mass production because it is relatively quick and cost effective.

However, there are also several advantages that make die casting an ideal choice for certain applications. For example, die casting can be manufactured to very tight tolerances, making it suitable for high precision parts.

Die casting is also strong and durable, making it ideal for parts exposed to high levels of stress and wear. Additionally, aluminum die castings are easy to drill, tap, or machine, allowing for a wide range of post-processing options.

As a result, die casting is a highly versatile manufacturing process that can be used to create a wide variety of parts and products.

Importance of quality control in die casting

Quality control is essential in any manufacturing process, but especially in die casting. Die casting is a complex process of injecting molten metal into a mold under high pressure.

If any part of the process is performed incorrectly, it can lead to defects in the final product.That is why die casting companies are strict quality control procedures in place.

These steps help ensure that each component of the die casting process is performing correctly and the final product meets all required specifications. Without quality control, die casting becomes an unreliable and ineffective manufacturing method.

In summary

Aluminum die casting is a process that has many advantages over other manufacturing methods.

Choosing the right alloy for your project and controlling the quality of the casting process to avoid common problems is critical. If you are looking for a high quality and durable product, aluminum die casting is your best choice.

Also Read:

author: Peter Yordanov

14